CGS Tool Hi-Velocity Series: High-Performance Carbide End Mills

Engineered for Alloys, Steels & High-Speed Machining

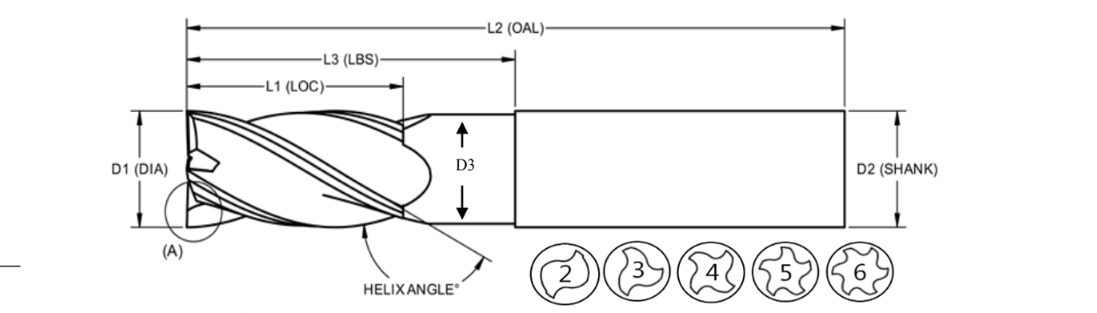

The HV Series End Mills from CGS Tool are designed to excel in alloys, steels, and other demanding materials where tool life and surface quality are critical. Built with variable helix and variable index geometry, the HV Series delivers superior performance at higher RPMs, reducing tool wear and eliminating the need for multiple tooling solutions.

Key Features of the HV Series

4-Flute Design – Provides excellent balance between strength, rigidity, and chip evacuation.

Variable Helix & Variable Index – Minimizes vibration and chatter for smoother cuts and extended tool life.

Coating Options:

ALTiN Coating for durability and thermal resistance at high speeds

AlCrN Coating available upon request for enhanced hardness and wear protection

Versatile Configurations – Offered in Square End, Ball End, and Corner Radius (CR) styles.

Metric and Inch Options – Full range of standard and metric sizes available.

Reduced Neck & Weldon Flats – Available upon request for specialized applications.

Custom Options – Special sizes, lengths, and radii available with quick turnaround.

Tool Styles Available

Square End Mills – Stub, Standard, Long Length, and Extended Reach designs for general milling.

Ball End Mills – Precision for 3D contouring and surface machining.

Corner Radius End Mills – Reinforced cutting edges for improved strength and reduced chipping.

Metric Corner Radius End Mills – Available with tight tolerances for international compatibility.

Performance Benefits

Better Tool Performance at Higher RPMs – Built to excel in modern high-speed machining.

Less Tool Wear in Alloys and Steels – Increases tool longevity in challenging materials.

Improved Surface Finishes – Delivers excellent results in both roughing and finishing applications.

One Tool, Multiple Operations – Reduces the need for multiple cutters, improving efficiency.

Why Choose CGS Tool HV Series?

Manufactured from premium carbide with tight tolerances (+.000”/-.002”)

Made in the USA for unmatched quality and consistency

Engineered coatings (ALTiN & AlCrN) for longer life in demanding materials

Backed by CGS Tool’s custom tooling capabilities for unique requirements