CGS Tool Storm Series: High-Performance Carbide End Mills — 3-Flute Power for Stainless, Titanium & Alloys

High-Strength End Mills for Exotic Materials

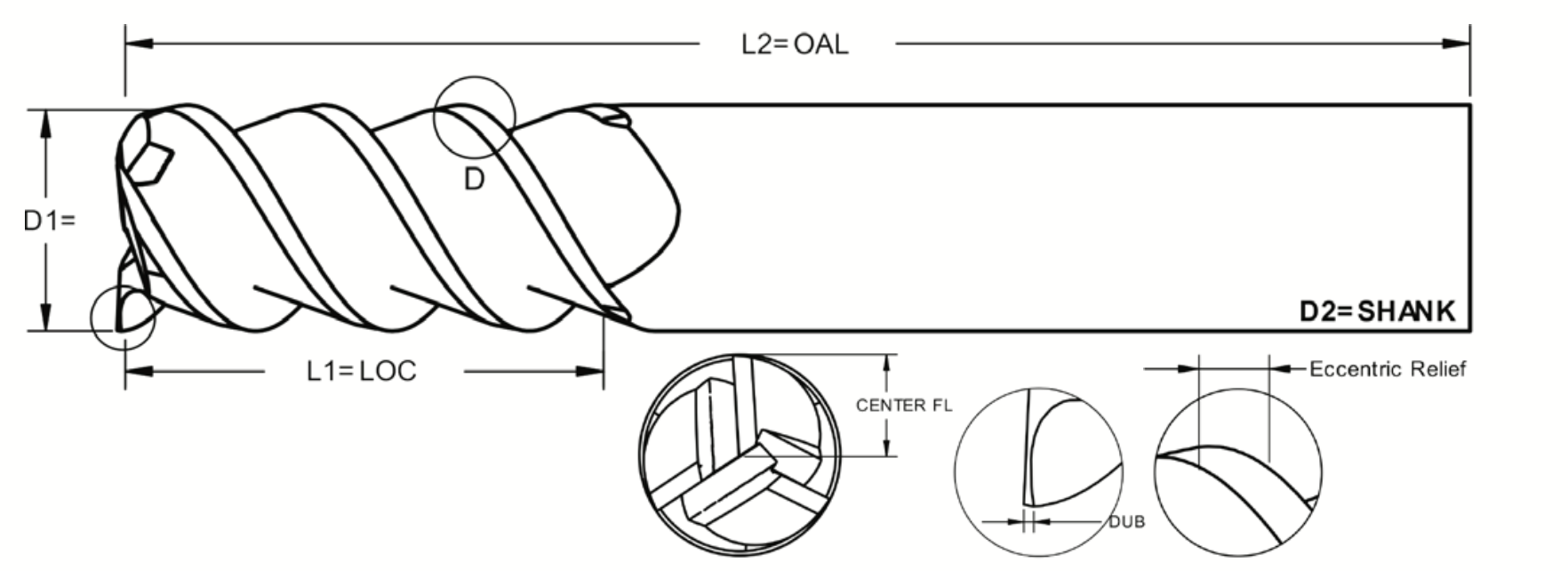

The Storm Series from CGS Tool is built for machining tough materials like stainless steel, titanium, Inconel, and nickel-based alloys. With a 3-flute, 60° hi-helix design and eccentric relief geometry, these tools deliver superior edge strength, stability, and surface quality — even in the most demanding applications.

Key Features of the Storm Series

3-Flute, 60° Hi-Helix Design – Ensures excellent chip evacuation and cutting efficiency.

Free Cutting Geometry – Reduces cutting forces while improving tool life.

HD Eccentric Relief Grind – Provides extra strength and stability to cutting edges, outperforming hollow-ground competitors.

High-Performance Applications – Optimized for stainless steels, titanium, Inconel, and nickel-based alloys.

Smooth Finishes – Produces stable wall finishes with less vibration.

Coating Options:

ALTiN Coating available (add “ALTIN” to the part number) for superior heat resistance.

Other high-performance coatings available upon request.

Reduced Neck & Weldon Flats – Optional configurations available.

Custom Options – Special sizes, radii, and lengths upon request.

Tool Styles Available

Square End Mills – Stub, standard, and long lengths for a wide range of applications.

Performance Benefits

Stronger Cutting Edges – Eccentric relief provides convex cutting support, giving the edge full strength under load.

Higher Feed Rates – Supported edges withstand radial forces better than hollow-ground competitors.

Longer Tool Life – Progressive wear is countered by thicker flute geometry.

Superior Performance in Exotic Alloys – Built to handle the toughest aerospace, defense, and medical-grade materials.

Why Machinists Trust the Storm Series

Made in the USA from premium carbide with tight tolerances (+.000”/-.002”).

Specifically engineered for difficult-to-machine materials like titanium and Inconel.

Advanced relief geometry increases reliability and finish quality.

Backed by CGS Tool’s custom tooling expertise for specialized applications.