CGS Tool VMAX (MX) Series: High-Performance Carbide End Mills

Precision Machining for Titanium, Alloys, and High-Temp Materials — 4 & 6 Flute High-Performance Tooling

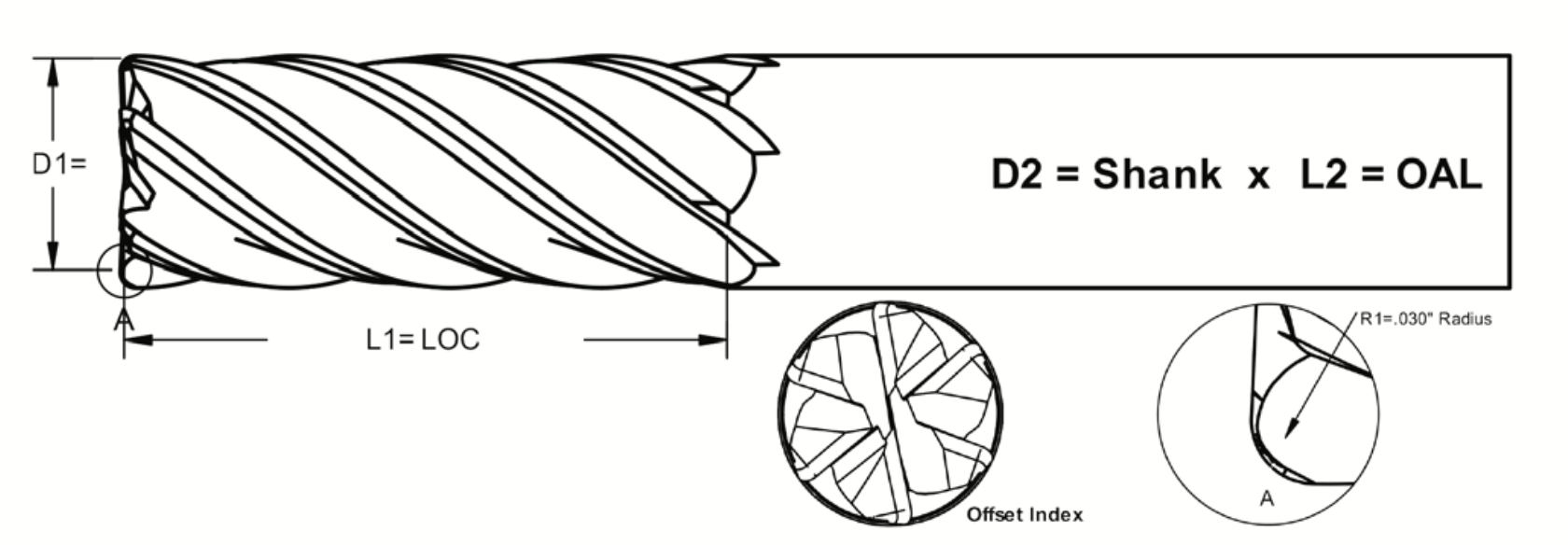

The VMAX (MX) Series from CGS Tool is engineered for maximum strength and stability in demanding machining applications. With a heavy core design and advanced coatings, these tools excel in titanium, stainless steels, and high-temperature alloys where rigidity and tool life are critical.

Key Features of the VMAX (MX) Series

4-Flute & 6-Flute Designs – Available in Square End and Corner Radius (CR) styles to match your application.

Heavy Core Geometry – Provides unmatched rigidity and minimizes tool deflection under load.

HD Eccentric Cutting Edge Prep – Reinforced edges for smoother cutting and improved wear resistance.

Variable Helix & Variable Index – Reduces chatter and vibration for superior finishes.

Coating Options:

nACRo High-Performance Coating for exceptional wear resistance in titanium and high-temp alloys.

AlCrN Coating Available upon request for extreme hardness and durability.

Custom Tooling – Special sizes, lengths, and radii available by request.

Reduced Neck & Weldon Flats available for specialized machining requirements.

Tool Styles Available

4-Flute End Mills – Square and Corner Radius, available in stub, standard, and long lengths.

6-Flute End Mills – Square and Corner Radius, optimized for rigidity and finish in tough materials.

Performance Benefits

Optimized for Titanium & High-Temp Alloys – Specifically designed for aerospace, medical, and defense machining.

Maximum Stability – Heavy core design reduces deflection in aggressive cuts.

Longer Tool Life – nACRo and AlCrN coatings protect against extreme heat and wear.

High-Speed Machining Ready – Variable helix and index geometry deliver smoother, faster cuts.

Why Choose CGS Tool VMAX (MX) Series?

Made in the USA from premium carbide with tight tolerances (+.000”/-.002”)

Engineered for extreme machining conditions in titanium and alloy steels

Available in both inch and metric sizes with flexible configurations

Backed by CGS Tool’s custom tooling solutions for specialized needs